E-Mail-Formatfehler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

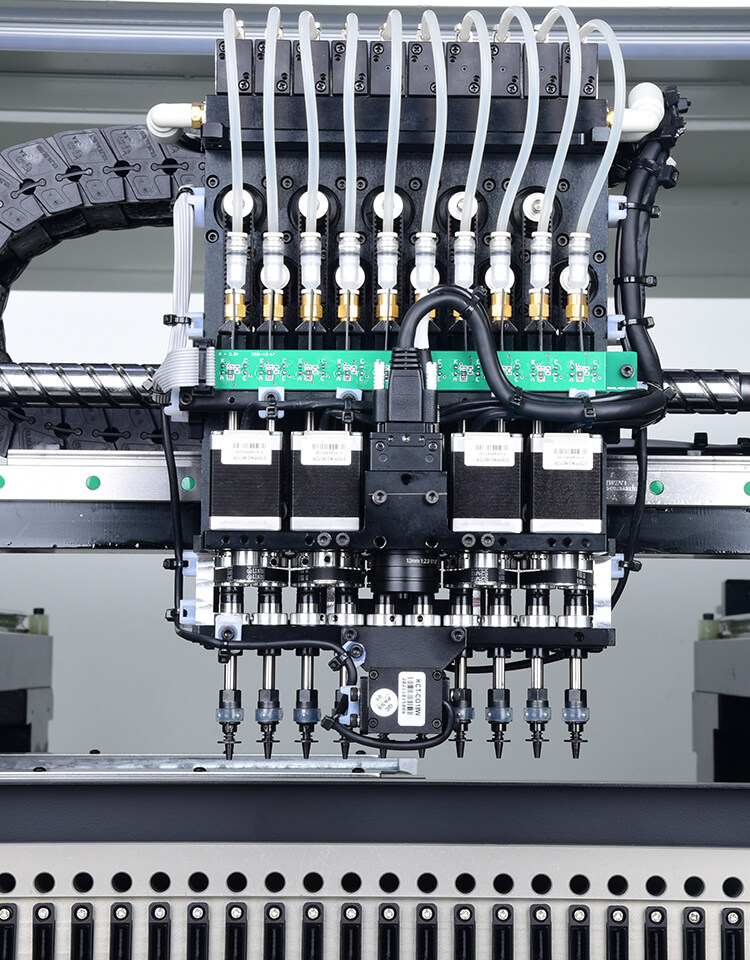

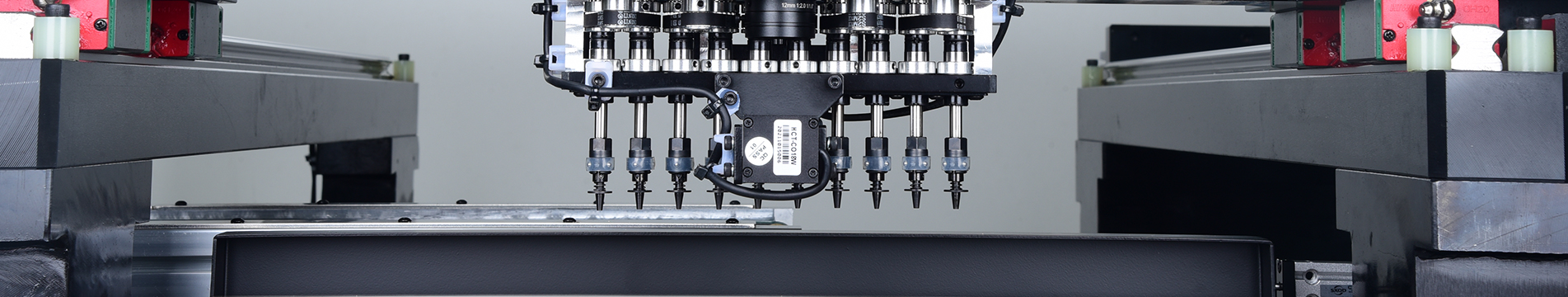

LED pick and place machines are among the most popular products manufactured by HCT. These machines are designed to automate the process of placing LED components on printed circuit boards (PCBs) with a high level of precision and accuracy. With the increasing demand for LED lighting, this machine is a vital tool for manufacturers looking to improve their output, reduce errors, and increase their production rate.

The automation SMT machines produced by HCT are another game-changer in the industry. These machines are designed to automate the entire SMT assembly process, from loading components to final testing. The automation process not only increases production speed but also reduces errors, improves quality control, and lowers labor costs, making it an attractive investment for businesses of all sizes.

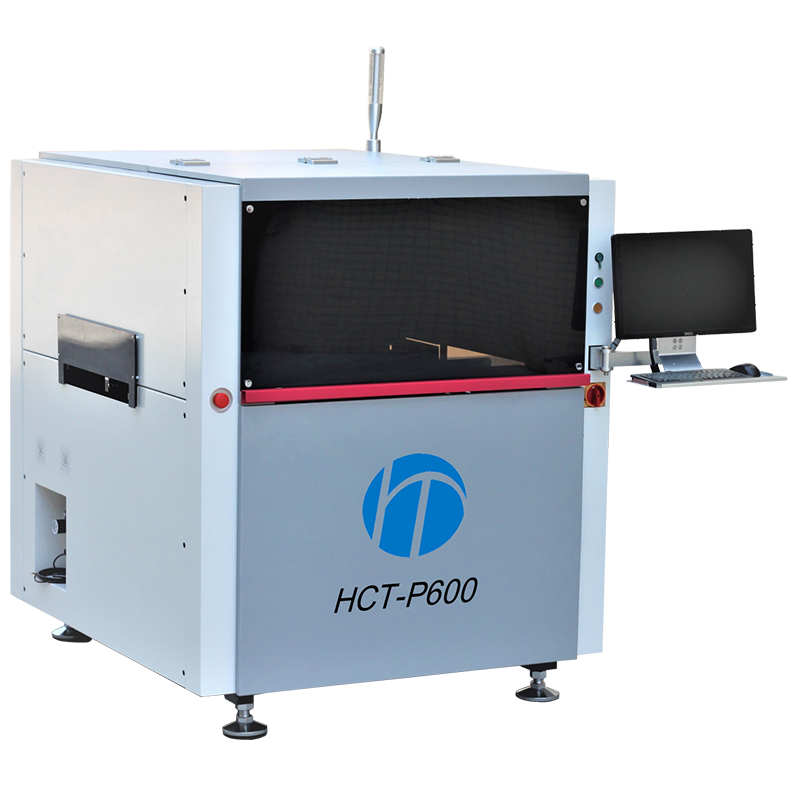

HCT also offers automatic stencil printers, which automate the process of applying solder paste to PCBs. This equipment has a high level of accuracy and precision, ensuring that the solder paste is applied in the right amounts and in the right place on the PCB. The automatic stencil printers are designed to work seamlessly with HCT's other SMT equipment, making it easy to integrate into existing production lines.

AOI testing equipment is another innovative product produced by HCT. The equipment is designed to inspect the PCBs after the assembly process to ensure that there are no defects, such as missing components or incorrect polarity. This machine uses advanced imaging technology to detect any defects in the PCB, which saves time and resources by eliminating the need for manual inspection.

HCT also provides customization of non-standard SMT surface mount assembly machines. This service ensures that businesses can get the equipment that suits their specific needs, even if it means designing and producing a unique machine that meets their requirements. HCT's engineers and technicians work closely with customers to understand their unique challenges and develop a customized solution that meets their specific needs.

Overall, HCT's products and services are designed to help businesses in the LED lighting and electronics manufacturing industry streamline their production processes, increase efficiency, and reduce costs. The company's commitment to innovation, quality, and customer satisfaction has made it a preferred partner for businesses looking for SMT solutions. With HCT, businesses can be assured of reliable, efficient, and high-quality equipment that meets their specific needs.

Solder Paste Stencil Printer

(3)1.2M Semi-automatic Solder Paste Printer

To direct the solder paste into the required locations, a stencil is employed. The stencil was used because the product shouldn't cover the full surface. Your "how to apply solder paste" issues are all resolved by the solder paste stencil. The paste is fed into the pick and place machine after being applied on the printed circuit board. This includes the elements that it holds in place.

High Accuracy Automatic Solder Paste Stencil Printer

The system offers three different cleaning techniques—dry cleaning, wet cleaning, and vacuum—that can be combined in any way and support manual cleaning in the production interface, cutting down on cleaning time and boosting production effectiveness.

Economical Full Automatic Stencil Printing Machine

The scraper beam of the gantry type can float the scraper head, and the scraper rises and falls automatically. All semi-automatic printing presses can employ stencils with the stencil bracket. the one-stage conveying system, the motor-driven precision ball screw automatic clamping device, and the PCB board automatic positioning.

SMT Peripheral Equipment

(9)SMT General Buffer Conveyor SMT Single / Dual Rail Conveyor

SMT Peripheral Equipment, Mass Soldering, Small Dip Soldering Machine, Pick & Place Machine, We take great pride in a great reputation among our customers for our exceptional product or service excellent, competitive rate, and also the best services. Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We warmly invite clients from all around the world to build long-lasting business relationships that benefit both parties and look forward to a bright future together.

DIP Wave Solder Infeed Conveyor - China Automatic SMT Infeed Conveyor

To accomplish the goal of welding, wave soldering involves bringing the plug-in board's welding surface into direct contact with the hot liquid tin. The primary component is solder bar.

Automatic Wave Soldering Unloader - China SMT Line Unloader Equipment

This conveyor is used to remove PCBs or pallets from an adjustable-angle wave soldering equipment. The downstream machine is shown a PCB or pallet at eye level by the decline part.

SMT Automatic PCB Loader Machine

Repair and maintenance procedures for the loader machine's gearbox include draining the oil, cleaning the interior with diesel or gasoline, and replacing the oil with new smooth oil after it has been drained. Add right away in the centre of the viewing area. In the future, changing the lubricating oil once a year is sufficient. The gearbox could become overheated from using too much lubricant, and an overloaded motor could activate the motor maintenance switch.

Plug-in Machine

(1)Automatic Visual Profiled PLUG-IN Machine HCT-YX540

HCT-YX540 automatic visual-profiled plug-in machine fully adopts the XY structure of an SMT mounter with high precision and fast processing speed. Compared to manual plug-ins, it has advantages like higher efficiency, a higher automation rate, better quality, and lower labor costs. The back frame seat is made of electroplated steel tube to ensure high strength and durable operation.