E-Mail-Formatfehler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

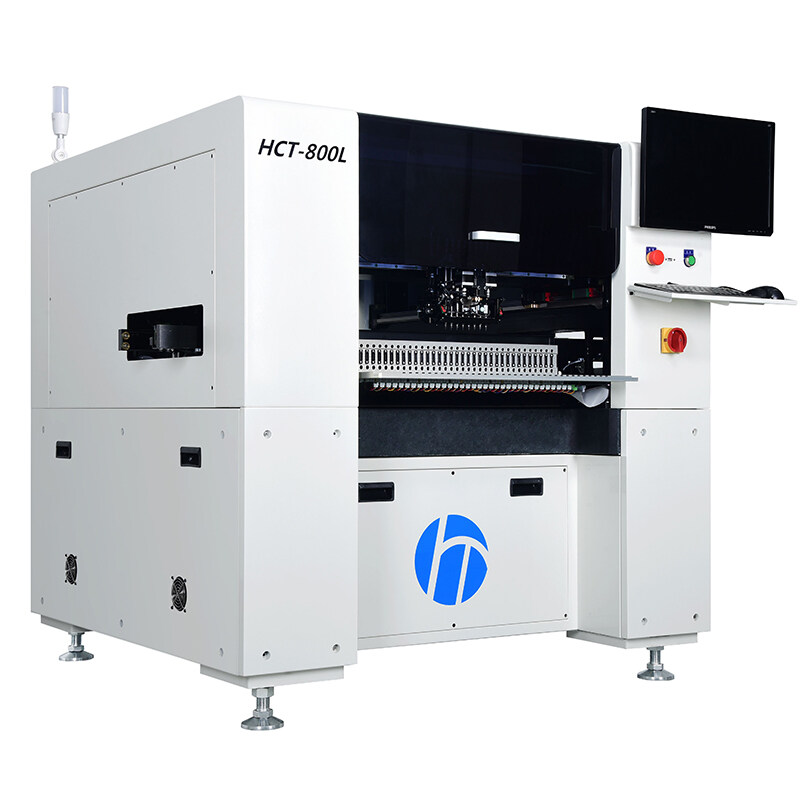

1.2M Semi-automatic Solder Paste Printer

To direct the solder paste into the required locations, a stencil is employed. The stencil was used because the product shouldn't cover the full surface. Your "how to apply solder paste" issues are all resolved by the solder paste stencil. The paste is fed into the pick and place machine after being applied on the printed circuit board. This includes the elements that it holds in place.

1.2M Semi-automatic Solder Paste Printer - Wholesale Solder Paste Stencil Printer

A 1.2M semi-automatic solder paste printer is a piece of equipment used in electronics manufacturing for the application of solder paste onto printed circuit boards (PCBs) before component placement. It offers precise and consistent solder paste deposition, improving the overall quality and efficiency of the soldering process.

Here are some key features and functionalities of a typical 1.2M semi-automatic solder paste printer:

-

Working Area: The printer provides a working area of 1.2 meters, allowing for the handling of larger PCBs or multiple smaller PCBs simultaneously. This extended working area accommodates various board sizes commonly found in electronics manufacturing.

-

Frame Alignment System: The printer usually incorporates a frame alignment system to ensure accurate positioning of the stencil (metal plate with openings) over the PCB. This system helps align the stencil with the pads on the board, ensuring proper solder paste deposition.

-

Stencil Support: A robust support structure holds the stencil in place during the printing process, maintaining stability and preventing movement that could affect the accuracy of solder paste application.

-

Solder Paste Application: The printer utilizes a squeegee or blade mechanism to apply solder paste onto the stencil. The squeegee moves across the stencil's surface, forcing the solder paste into the openings and depositing it onto the PCB pads.

-

Smooth Motion Control: Precise motion control is essential for achieving accurate solder paste depositing. The printer incorporates a motorized system that controls the movement of the squeegee, ensuring smooth and controlled strokes across the stencil.

-

Adjustable Parameters: Operators can adjust various parameters such as squeegee pressure, speed, and angle to optimize the solder paste application for different PCB designs and requirements. This flexibility allows for fine-tuning to achieve optimal solder paste volume and consistency.

-

Vision System (Optional): Some models may include a vision system that captures images of the PCB and stencil to verify alignment and ensure accurate solder paste deposition. This feature enhances the printer's accuracy and reduces errors.

-

User-friendly Interface: The printer typically has an intuitive user interface that allows operators to set up printing parameters, monitor the process, and make adjustments easily. This simplicity enables efficient operation and reduces setup time.

1.2M semi-automatic solder paste printer offers precise and reliable solder paste application for PCB assembly. It streamlines the production process by automating the critical step of depositing solder paste onto PCBs, leading to improved solder joint quality and overall manufacturing efficiency.

TECHNICAL PARAMETER - Semi-automatic Solder Paste Printer

|

Model No. |

HCT-1288 |

|

Printing Table Size |

320 x 1200mm |

|

Frame Size |

370×470mm-420×1400mm |

|

Max PCB Size |

Maximum 300 × 1200mm (customizable size) |

|

PCB Thickness |

0.2 ~2.0mm |

|

PCB FixedMethod |

PCB Outer Or Pin Positioning |

|

Platen fine-tuning |

Front/back ±10mm R/L ±10mm |

|

Printing Accuracy |

± 0.05mm |

|

Machine Repeatability |

± 0.02mm |

|

MinimumSpacing |

0.35mm |

|

Compressed Air |

4-6kgf / cm2 |

|

Power Supply |

Single Phase 220V 50/60HZ / 100W |

|

Dimensions |

L1370 × W680 × H1650 ± 20mm |

|

Weight |

Approx.350kg |

SPECIFICATION - Semi-automatic Solder Paste Printer

- Using precision guide rail and the import motor to drive the blade seat conversion, printing, and high accuracy.

- Printing scraper can rotate 45 degrees fixed up, easy printing stencil and squeegee cleaning and replacement.

- Block can be adjusted before and after the blade, to choose the right printing position.

- Combined with a fixed groove printing platen and PIN, easy installation and adjustment, for single, double sided printing.

- School Edition way to move a steel mesh, combined with printed (PCB), X, Y, Z. Convenient fine adjustment.

- Can be set to one-way and two-way, a variety of printing methods.

- With the automatic counting function to facilitate the production of output statistics.

- Adjustable blade angle, steel blade, rubber scrapers are suitable.

- Touch screen with a screen saver function, the time can be adjusted to protect the touch-screen life.

- Printing speed display can be adjusted.

How to Use Solder Paste?

Solder paste is the go-to tool for mass PCB assembly and prototype PCB assembly. The product is also used to establish electrical connections on printed wiring boards.

A solder paste stencil is used to guide the paste into the areas where it is needed. The product should not go on the entire area, hence the stencil. The solder paste stencil solves all your “how to apply solder paste” problems. After being applied to the printed circuit board, the paste is passed into the pick and place machine. This adds the components which are held in place by it.

Even though the components are stuck, it is best not to move the board too aggressively since the pieces could still move or fall off. You have a few hours to solder the board before the paste starts to deteriorate.

HCT - Semi Automatic SMT Solder Paste Printer

HCT is a recognized manufacturer in China that specializes in the production of semi-automatic SMT (Surface Mount Technology) solder paste printers. These printers are essential in the PCB assembly process as they precisely apply solder paste onto the pads of the printed circuit boards before component placement.

HCT's semi-automatic SMT solder paste printers are designed to provide accurate and consistent solder paste deposition, ensuring high-quality solder joints. These printers often come equipped with features such as vision alignment systems, programmable controls, adjustable stencil frames, and user-friendly interfaces for easy operation.

The semi-automatic nature of these printers allows for efficient manual loading and unloading of PCBs. They strike a balance between cost-effectiveness and productivity, making them suitable for various manufacturing environments.

To make an informed decision, it is advisable to review HCT's product specifications, customer reviews, and warranty terms. Additionally, contacting HCT directly or reaching out to their authorized distributors can offer further clarification and guidance on selecting the right semi-automatic SMT solder paste printer that meets your specific requirements.