E-Mail-Formatfehler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

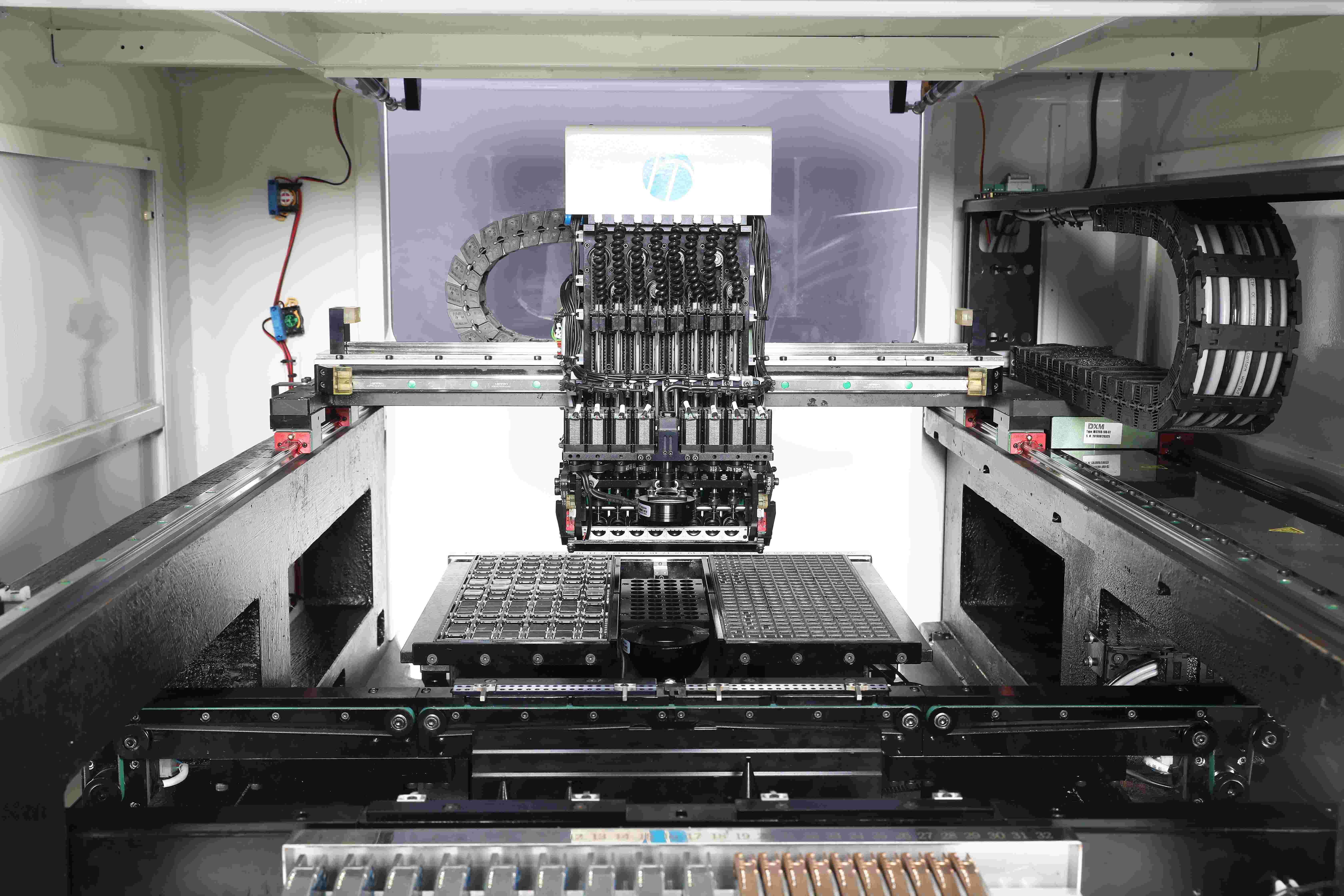

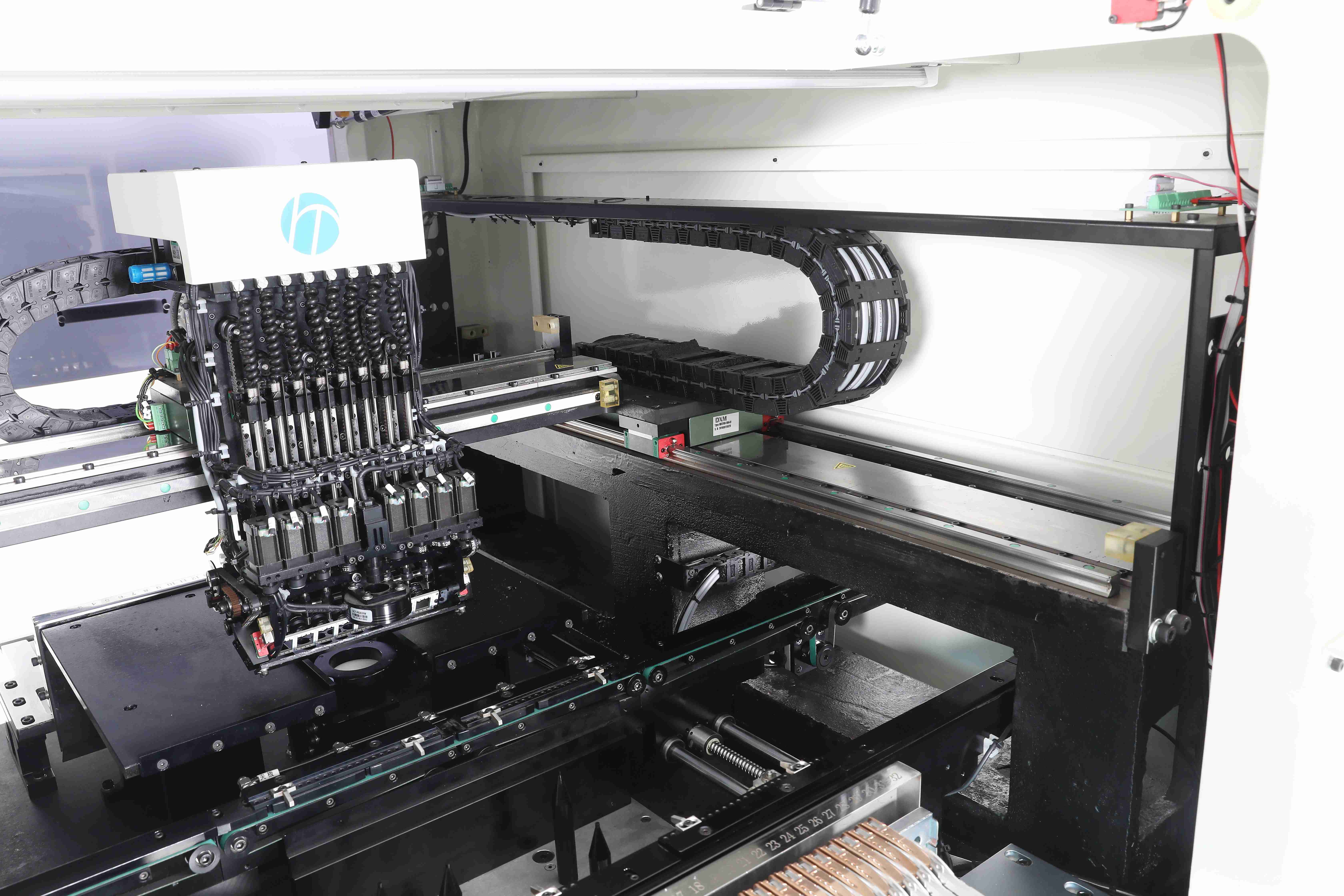

HCT-800S General Automatic SMT Chip Mounter

An intelligent piece of precision equipment known as an SMT pick and place machine is not only big and complicated to use, but also intelligent. Without conducting a thorough study, we do not advise you to use the phone directly.

As HCT-800S SMT Pick & Place Machine that equipped with 8 heads as well as a new flying vision system, the HCT-800S realizes a optimum chip mounting speed of 32,000 CPH. In addition, it is applicable to 0402 chips to the largest 30mm ICs by default and increases actual productivity and placement quality by applying a smart nozzle checking and replacing system.

Technical Parameters - HCT-800S General Automatic SMT Chip Mounter

|

Model |

HCT-800S |

|

|

Number of Heads |

Vision on the Fly |

8 |

|

Placement Rate |

Under the optimum condition |

32000CPH |

|

IPC9850 |

26800CPH |

|

|

Feeder Capacity |

Front and Back |

25 Tape Feeders (8mm/12mm Electric Standard) 25+25 Tape Feeders(Optional) |

|

IC Tray Capacity |

325 x 135mm |

2 |

|

Component Alignment |

Vision Detection视觉识别 |

|

|

Component Sizes |

Handled by Head Camera |

Smallest: 0201 (inch) |

|

Largest: 10 x 8 (mm) |

||

|

Handled by Fixed Bottom Camera |

Smallest: 1206 (inch) |

|

|

Largest: 30 x 30 (mm) |

||

|

Resolution

|

X/Y Axis |

Magnetic Levitation Linear Motor |

|

Z Axis |

Step-Servo Motor |

|

|

Rotation |

0 to 360° |

|

|

Placement Accuracy |

±0.05mm |

|

|

X-Y Repeatability |

Magnetic Grid |

±0.002mm |

|

PCB Size |

Maximum |

L 300 x W 250mm |

|

|

Minimum |

L 50 x W 50mm |

|

In-line Conveyor |

|

3-Section Transmit |

|

Programming |

Vision Teach-in |

|

|

Coordinates Import |

||

|

Main Control |

|

Industrial PC |

|

Power |

AC 220V±10% (50/60Hz, 1 phase) |

|

|

Max. 3.0KW |

||

|

Air Pressure |

0.55-0.7MPa (5.6-7.1kgf/cm2) Built-in vacuum pump for nozzles |

|

|

External Dimension(mm) |

L x W x H |

1150 x 1370 x 1500 mm |

|

Mass |

Approximate 1300kgs |

|

Product Features - China SMT Led Chip Mounter Machine

1. Vision On the Fly Alignment

2. Bottom Vision Alignment System for big components/IC

3. Fiducial recognition and coordinate correction

4. Three-section conveyor system with SMEMA interface and automatic-width-control

5. Magnetic levitation linear motor in X and Y axis for high repeatability and stability

6. Smart Nozzle System provides automatic nozzle checking and replacing

7. Perfect for medium & high volume production

8. Strong and rigid mechanical design

9. Optimized pick/place routing design, ensures precision and speed

10. Each mounting head has its Z - direction step-servo motor, which is designed for vertical motion

11. Works with different types of high-precision nozzle

12. For different PCB, FPC, MCPCB, PSB, etc. Suit for a variety of SMD components: resistors, capacitors, IC, QFP, CFP, etc.

13. Using imported high-precision ball screws, motors, solenoid valves, cables, etc., effectively improves placement accuracy, and stability.

Precautions when using the pick and place machine

1. Before using the pick and place machine, we need to have a general understanding of the entire operation process of the pick and place machine, so that we can avoid various errors in use.

2. During the operation of the pick and place machine, if there are various faults in some positions and parts need to be replaced, we need to press the emergency button or shut down the machine before we can perform the replacement operation.

3. Since the pick and place machine is relatively heavy, it must be properly grounded during use and cannot be placed on the board or in uneven places for production work.

4. In the workshop where the pick and place machine is produced, keep the ambient temperature such as temperature and humidity normal at all times. There should be no flammable or explosive materials around the production vehicle. Fire-fighting appliances need to be placed within the designated area and safety precautions must be taken.

5. In the process of operating the pick and place machine, we must ensure that all organs of our body are at a safe distance. Always keep hands and heads out of the safety door before starting the machine.

Product Display - China SMT Led Chip Mounter Machine