E-Mail-Formatfehler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Dual Wave Soldering Machine

When wave soldering boards are populated with SMT components, these components can impede the laminar flow of the main wave. This is the reason for the occurrence of opens, that is, unsoldered joints on the SM device. To overcome this and to safely process boards with SM devices, very dynamic press-solder waves are installed, whose main purpose is to wet the pads and the leads. Excessive solder that may be found on these wetted leads is afterward removed again by the main wave. The terminology dual wave soldering refers to the fact that two solder nozzle/solder wave are used in this process.

The Wave Soldering Systems are the economic solution for easy start-up of PCB production, solid, dependable, yet cost-effective. We offer professional products and services, welcome to work with us.

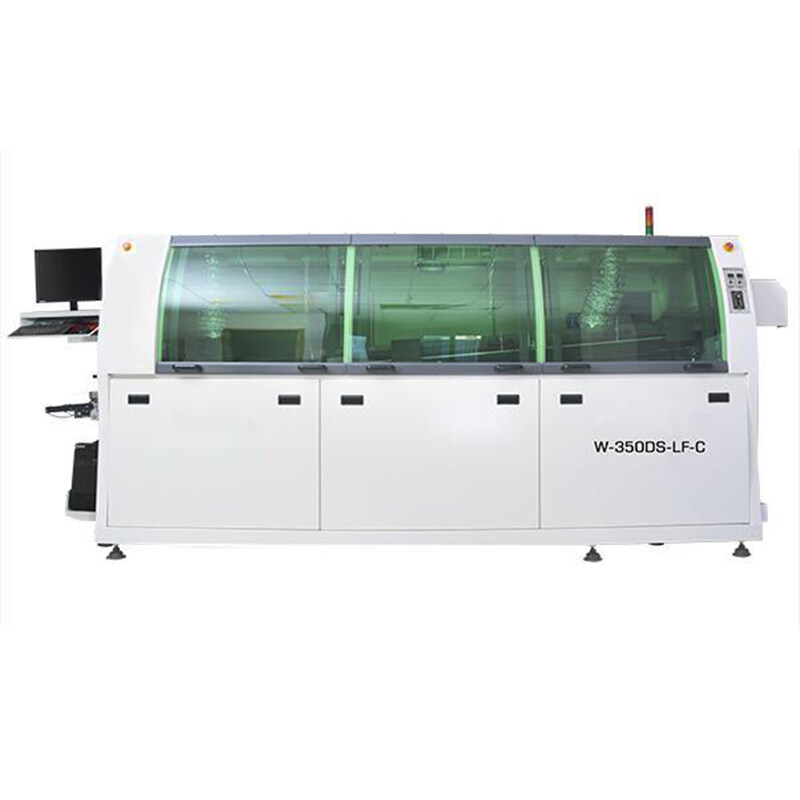

Lead-Free Double-Wave Computer-Controlled Soldering System

Internally modular and with a streamline architecture, it can solder SMT and DIP components without using lead. In order to stop the soldering flux from dripping onto the PCB, the spraying system uses a centrifugal fan to collect air. Sensor for the soldering flux buffer tank is external, more dependable, and robust.

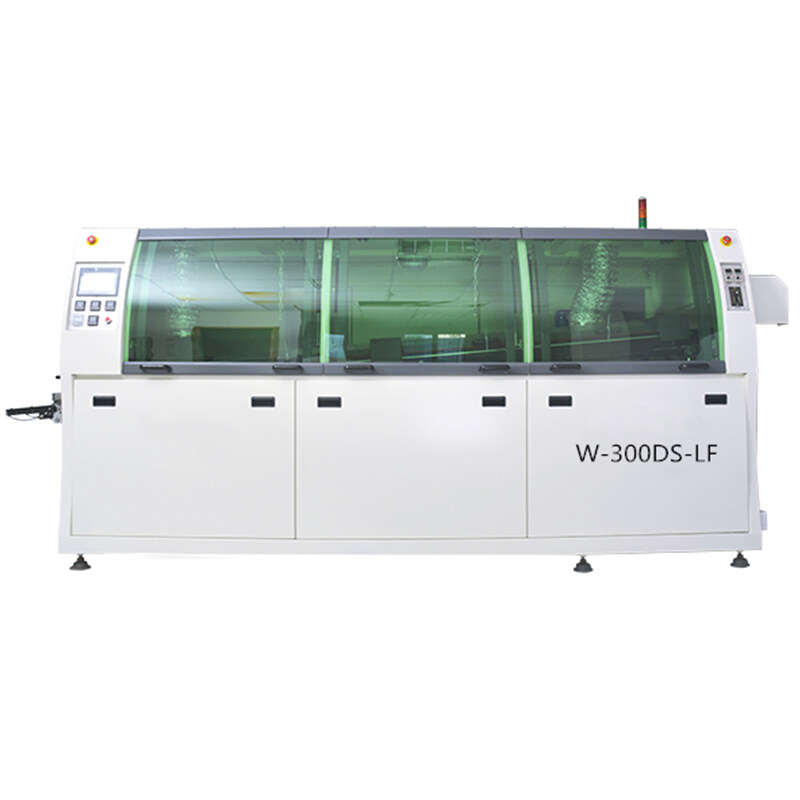

Small Lead-Free Double-Wave Soldering Oven

Flux spray system with accurate and dependable PLC control, scanning spray nozzle, Japanese nozzles, and rodless pneumatic cylinders. With non-level frequency conversing speed adjustment and auto-synchronous board feeding features, the conveying power system is automatic. The preheating system uses remote infrared ceramic heating pipes, which guarantees a good heat preservation effect, a quick heating up time, and an even temperature.

Economic Lead-free Double-Wave Soldering Machine

Effective, energy-saving, environmentally friendly, lead-free, safe, and brand-new design, with easy operation and convenient maintenance. Automatic board input, automatic power system, and automatic frequency converter control. Flux spray system with accurate and dependable PLC control, scanning spray nozzle, Japanese nozzles, and rodless pneumatic cylinders.